In Roll Forming Process Which Rollers Are Used

Roll forming is a well-known process used to manufacture long sheet metal products with constant cross-section. After the final forming station the.

What Is Roll Forming National Material Company Steel Processing Facilities

In most cases they are also the powered drive rolls that pull the strip through the roll forming unit.

. The process is performed by sets of mated rollers that change the form until the desired cross-section or shape is attained. Side-rolls do the same work as the main rolls. The common metals used in roll bending machines are steel and aluminum.

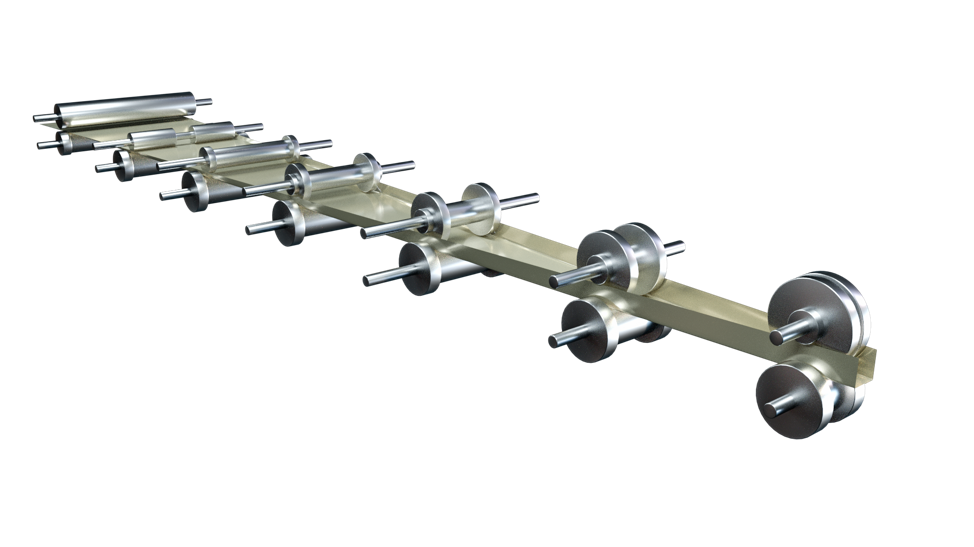

Four-roller plate bending machine Three-roller plate bending machine Plate bending machine As shown below. Simulation of roll forming process. The standard forming dies for roll forming are mated pairs of dies that mount on a series of spindles.

First there is the entry section where the material is loadedusually in sheet form or fed from a continuous coil. Too few forming steps will twist the product. To avoid forming defects and to reduce the process development efforts finite element analysis can be used to predict strain distributions and sheet geometry during and after the process.

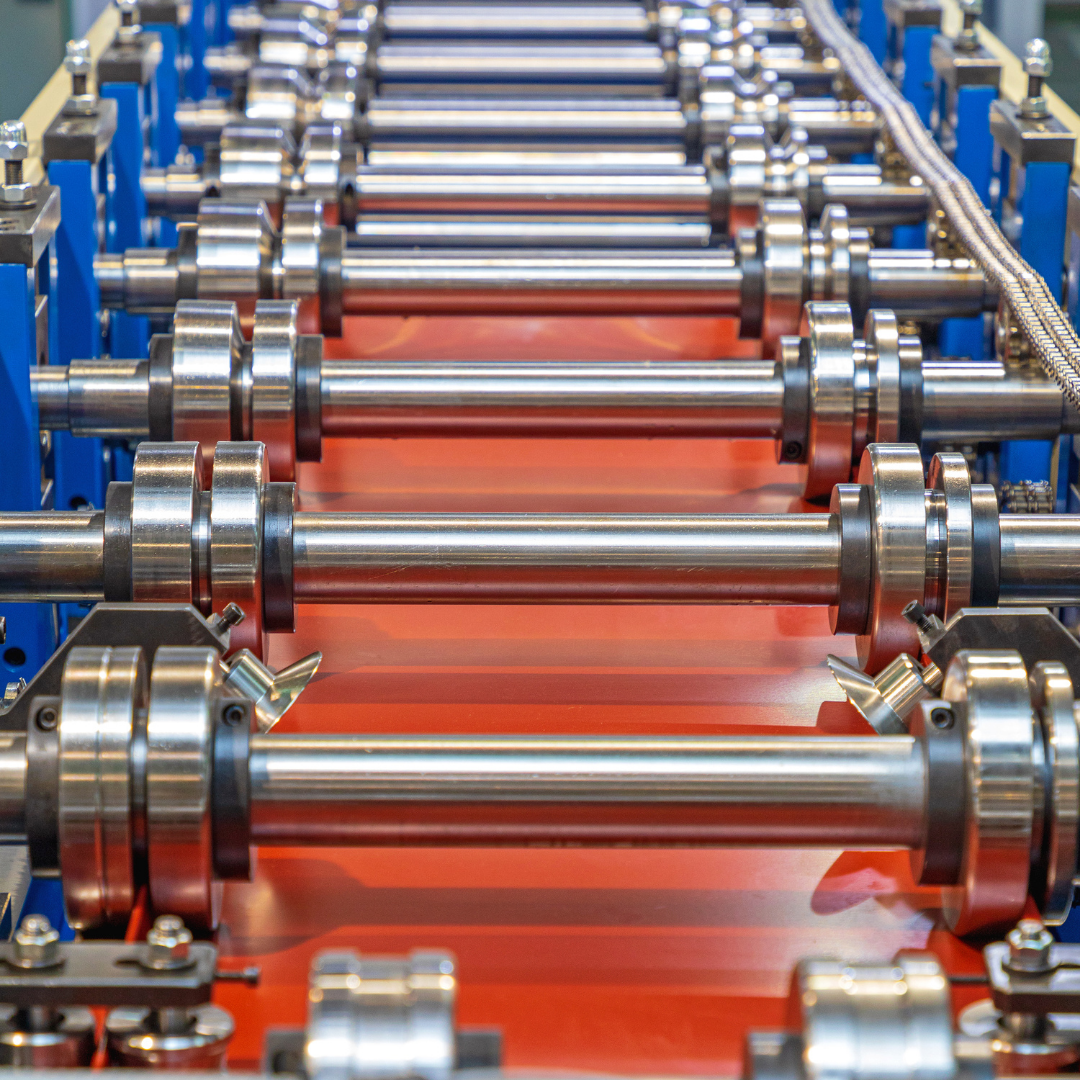

Cold Roll Forming Machines Rollers are the main parts of a roll forming machine line. It is placed on a machine called an uncoiler or decoiler. It is characterised by high progress high speed low scrap and one-off.

The typical roll forming machine line has four major parts. Cold Roll Forming Machines Rollers Design Process The aim is to form the desired profiles within the specified tolerance with the least amount of forming steps. Stainless steels of various alloys 300-series or 400-series aluminum or copper are also used.

Firstly cutting raw material in length and prepare for the first step machining. For some machines the forming rollers are also the drive rollers. Here the metal is cut according to the specifications the machine has been set to.

Station rollers shape the metal and are the main driving. A-48 This approach can be applied to a conventional roll forming line. These rollers can be as simple as the cylindrical rollers used to roll luggage through airport scanners or they can take on more intricate shapes.

The last section of a standard roll former is the exit station. All the profiles formed by the rollers. The second section is where the roll forming process begins.

The rollers not only shape the metal they also. In addition to the conventional forming rolls mounted on parallel horizontal shafts side rollers are frequently used for many forming operation. Definition Roll forming is a method in which the sheet material is placed in 2-4 rollers of the plate bending machine and the sheet material is bent and formed along the roller as the roller rotates.

The third part is the cut off press. And this roll forming process is used in automobile and construction area which manufacture the same shape of mass-product. We acknowledge this kind of Roll Forming graphic could possibly be the most trending topic past we ration it in google gain or facebook.

Material Options for the Rollers Used in Roll Bending Machines Metal. The roll forming process is a multi-step process. Roll Forming Machine is a processing machine that passes rolled steel or other long strips of metal through a series of Hardened Steel Rollers which are controlled using a pre-set PLC code to achieve a specific processing operation on the sheet metal at each station to produce a specific metal part.

Roll forming is most typically done with coiled low carbon steel of various gauges. The cold roll forming process makes the intended section of shape by the coil gets through the rollers in a raw. The rollers are precision-contoured metal dies that shape the incoming sheet metal.

Roll forming is a process in which a strip or sheet of metal such as steel is passed through a continual set of stands rolls until the desired cross-section profile is achieved. Secondly lathe machining for the roller. Side-rolls are extensively and successfully used in tube forming and should be more widely used in roll forming machine.

What Do Roll Forming Machines Do. Using a patented process A-48 R-9 forming rolls with the part shape along the circumferential direction create the desired form as shown in Figure 8. Roller forming also known as roll forming or cold rolling is a process in which metal is formed continuously from sheet strip to coil through a series of roll stations equipped with roll forming sometimes called roll die to produce a uniform cross-sectional shape.

Next up are the station rollers where the actual roll forming takes place. Its submitted by admin in the best field. Roller Dies are the important parts of roll forming machine equipment.

The station rollers shape the metal as well as drive the metal through the machine. In most cases they are also the powered drive rolls that pull the strip through the roll forming unit. Here are a number of highest rated Roll Forming pictures upon internet.

The rollers are precision-contoured metal dies that shape the incoming sheet metal. Most rollers are made of hard-chromed steel or stainless steel. Drive rollers Drive rollers are used to move the metal through the machine.

It is a process used to convert long strips of metal into various cross-sections or shapes. Urethane can be formulated in several hardness levels to handle a broad range of products. The roll dies one male and one female rotate vertically to progressively form the desired roll formed shape.

In roll forming quality of. This forming process is primarily focused on the cross-section of the metal or material. One advanced forming technique for fine tuning a roll formed profile is the use of side rollers.

Depending on the complexity of the profile as many as fifteen such roll die. Roller process is heat treatment. Forming rollers are put together in a progressive series to complete a process used to form the end product.

Roll Stamping creates additional shapes and features beyond capabilities of traditional roll forming. The sheet metal usually begins in a continuous coil. The steps of the rollers die process including.

We identified it from reliable source. The sheet or strip is plastically deformed along a linear axis in a room temperature environment. The sheet metal passes through a series of rollers.

Roll Forming Die and Processes. Especially other process has been changed to cold roll forming process due to reduce the cost of production recently. These rollers can be as simple as the cylindrical rollers used to roll luggage through airport scanners or they can take on more intricate shapes.

Typically used to create parts featuring long lengths roll forming is also useful for. Bending process of plate bending machine. The sheet metal then enters the roll forming machine.

Steel rollers are typically the leading.

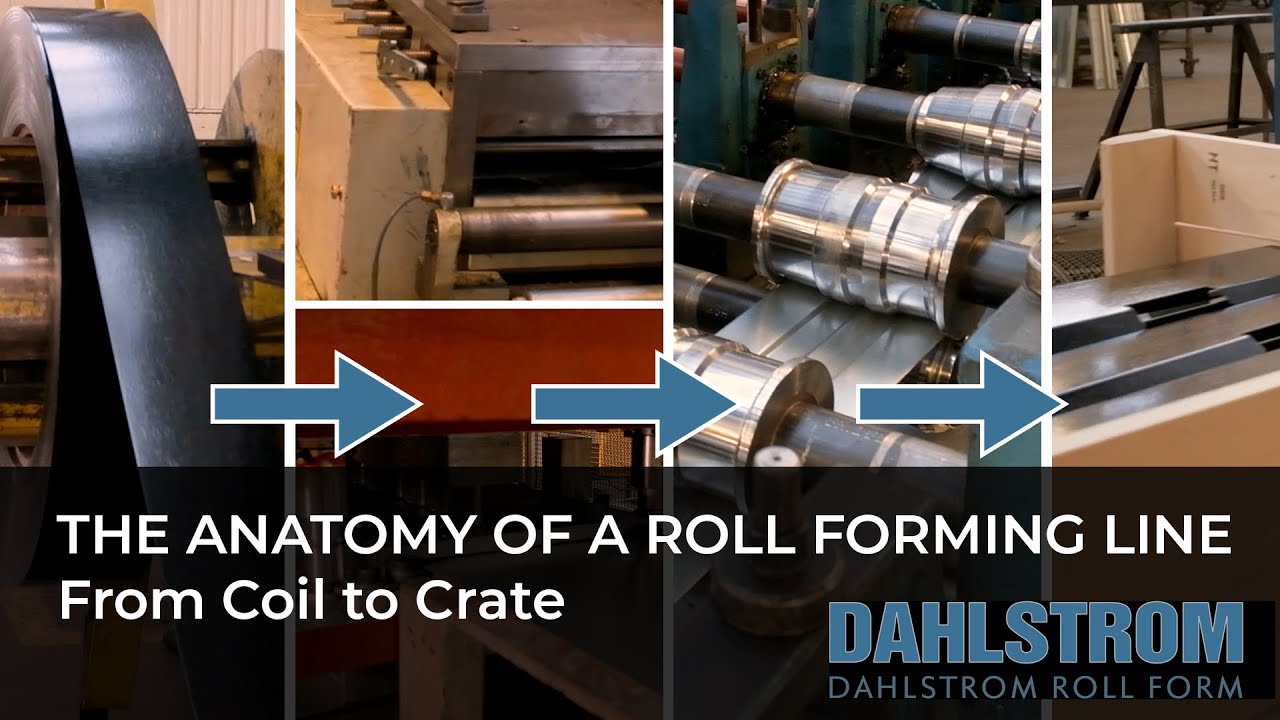

The Anatomy Of A Roll Forming Line Complete Process From Coil To Crate Youtube

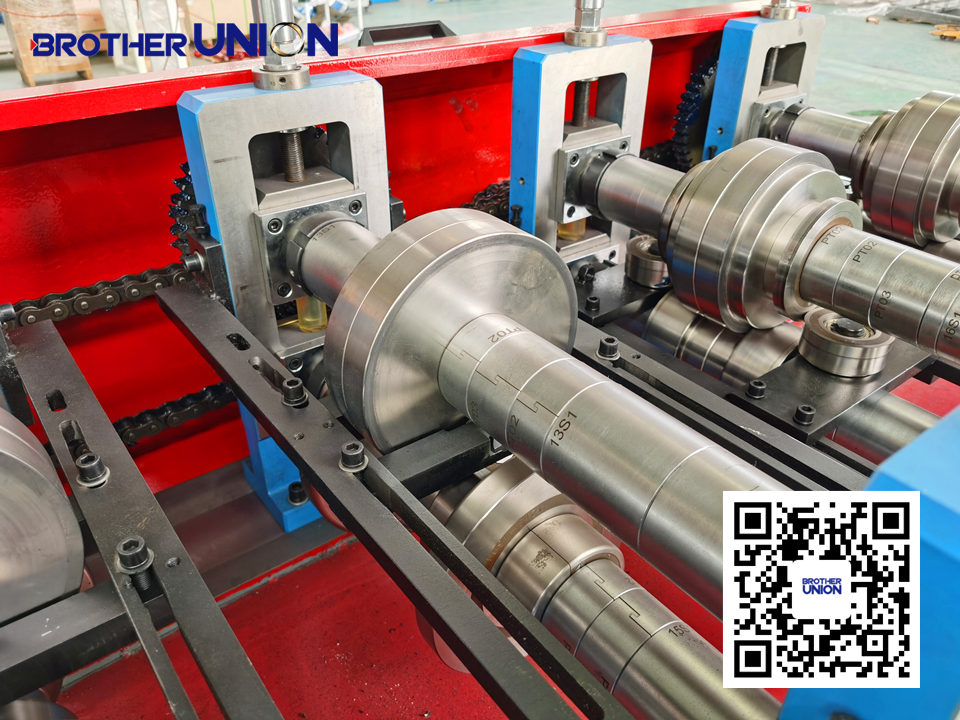

Spacer In Roll Forming Mill Brother Union Roll Forming

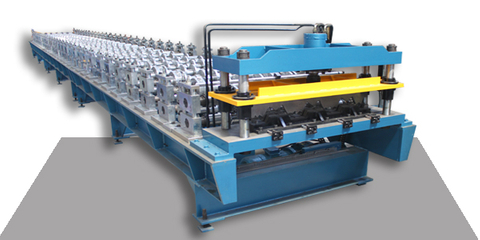

Corrugated Sheet Roll Forming Machine Corrugated Sheet Making Machine

Roll Forming Machine Manufacturers Roll Forming Machine Roll Forming Machine

How To Choose Roll Forming Machine And Its Application Steelmama

Roll Process Of Bow Shaped Sheet Metal Parts In The Forming Roller Download Scientific Diagram

The Flexible Roll Forming Frf Process A Schematic Representation Download Scientific Diagram

Roll Forming Custom Roll Forming Process Roller Die

Illustration Of The Roll Forming Machine A The Working Principle Of Download Scientific Diagram

What Is Cold Roll Forming Machine Steelmama

Components Of The Roll Forming Mill Download Scientific Diagram

The Profile Forming By Die Bending Process Fig 2 The Profile Forming Download Scientific Diagram

Roll Forming Process Vietnam Roll Forming Machine Cunmac Vietnam

Roll Forming Tri State Fabricators

What Is Metal Roll Forming Roll Forming Lines

Roll Form Process What Is A Roll Forming Machine

Comments

Post a Comment